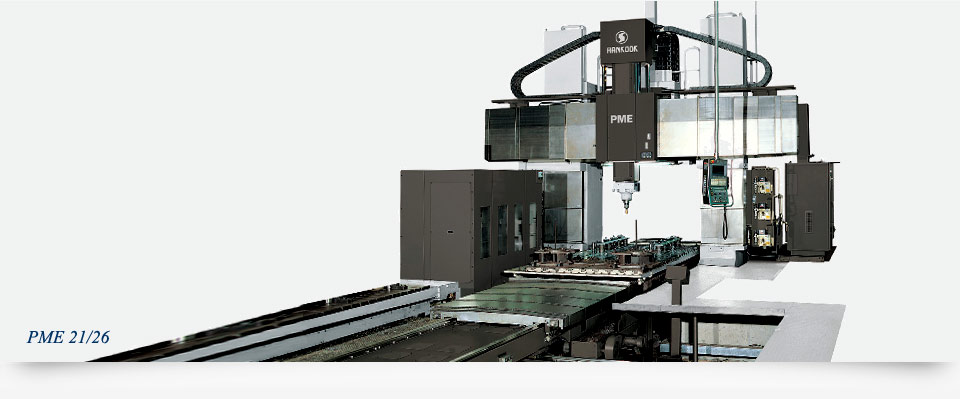

• One-piece casting structure of the bed,

• column and cross-rail provide stability,

• rigidity and accuracy.

• Vertical spindle head can be

• configured with optional attachments

• offering optimal machining for

• any application.

• Continuous multi-phase and sequential machining

• operations can be accomplished with

• the Automatic Attachment Changer.

• Substantial and rigid square 380/500/600mm

• Ram and 1000/1500mm stroke Z-axis give

• flexibility for heavy duty machining.

• Hydrostatic guideway structure for X-axis

• to keep low friction, less wear, stable accuracy

• and smooth motion even at low speeds.

• Maximize the efficiency with Auto Tool Changer,

• Auto Pallet Changer, Auto Attachment Changer

• or other offered options.